The PDDL4J solver - In-company Tests

...

PDDL4J already collaborated with industrials. Our first tests provided productivity gains of between 5 and 50 % compared to in-house solutions or classical scheduling software. But, more than productivity gains, PDDL4J brings other benefits

The PDDL4J solver - Results

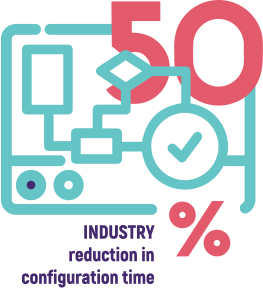

Industry

Need

Configure, manage, optimize a production chain (duration X, references Y, priorities, etc.).

Result

50 % reduction in reconfiguration time.

5 % to 6% gain in daily production yield.

Additional benefits

Priority criteria taken into account.

Automatic reconfiguration of the production line.

Automatic planning of prduction commands with handling of unforeseen events.

Prediction of production yields.

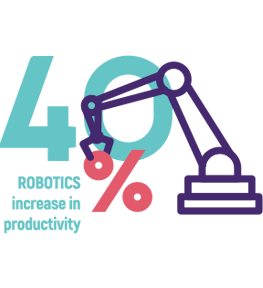

Robotics

Need

Supervision of a fleet of AGV robots (trajectory, actions, energy, requirements, etc.).

Result

40 % optimisation of prodution when using 1 robot.

50 % optimisation of prodution when using 1 robot.

Additional benefits

Optimisation of cost for an order.

Performance of a production line can be simulated basedon initial hypotheses.

Specific constraints can be integrated into the supervision software.

Reconfiguration of the production line can be automated.

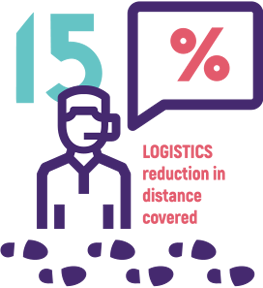

Logistics

Need

Reduce the distance covered by an operator in a warehouseduring "pick and place" actions.

Result

15 % reduction in the distance covered by the operator.

Additional benefits

Optimisation of the trajectory.

Real-time reconfiguration of the trajectory.